F10 Neo Driver

masterpiece of engineering

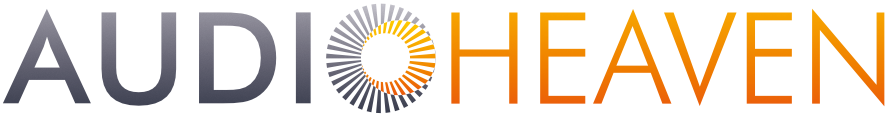

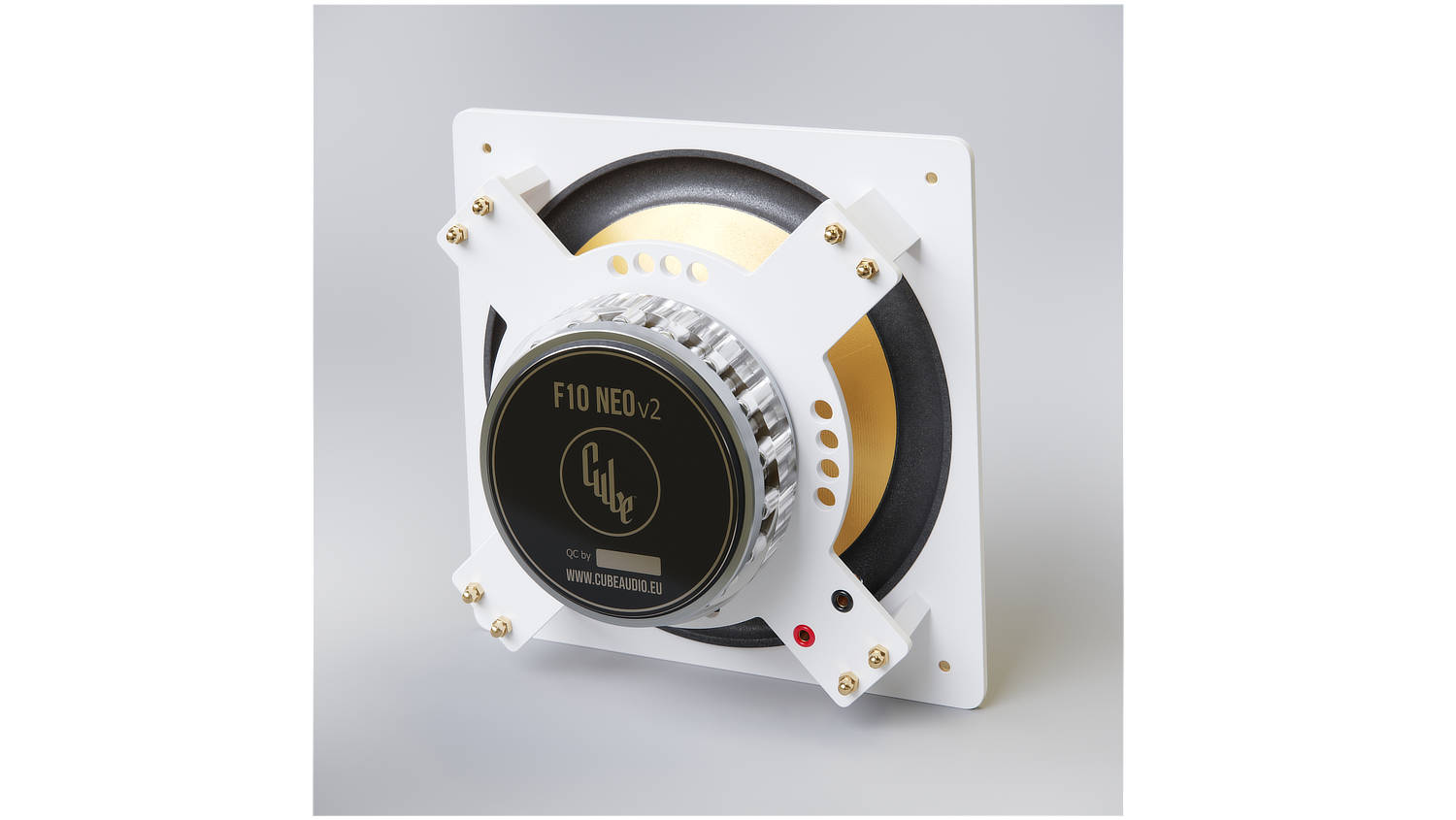

Cube Audio F10 Neo is a new 10″ fullrange driver. With ultra-powerful neodymium magnet motor and new cone geometry new Cube Audio 10 inch flagship drivers are now available.

F10 Neo has been updated to version 2. You can expect it now to be have even more bass, higher top end extension with slight reduction of upper mid-range at the same time.

F10 Neo Driver Details

We believe that fullrange speakers can create an illusion of live music that multiway loudspeakers struggle to match. Amazing soundstage, absolute holography, magical midrange, open and direct sound that gives you the most emotional presentation possible of your favourite music.

If you have ever heard a good implementation of the fullrange speaker, you know exactly what we are talking about.

We are very happy with the performance of Cube Audio 8″ drivers. Plenty of positive feedback from our happy customers, very enthusiastic reviews, but there still was this … “we should do more”. We knew that if we wanted to go into “even more fullrange regions”, we would have to increase the size of the driver. The answer was 10″ design, and it happened to be a very good choice. First of all, the size increase is meaningful enough so that it really makes a difference, but on the other hand, we had to overcome plenty of traps placed by mother nature. Physics is heartless and it really did everything it could to play with us “the hard way”.

Magnetic motor

Research and development process of 10″ drivers lasted for over a year. The goal was to end up with something completely new, that outperforms our 8″ inch drivers in nearly all aspects. To reach our dream performance one thing was sure, due to increased moving mass, the more powerful motor design was necessary. Two new motors were developed for that purpose. One being mixed ferrite & neodymium magnets assembly and the second one is constructed completely out of neodymium magnets. The full Neodymium magnet motor contains 81 magnets with a combined weight of 1480 grams and is capable of delivering 2.4 Tesla in the magnetic gap that is 9 mm high.

The voice coil is completely underhung with +- 3 mm excursion in 100% magnetic field strength. The maximum excursion is +- 6 mm. Since the voice coil practically does not leave the magnetic gap, with uniform field strength along all the gap height, the raw power, linearity and reduction of distortions are at their best. In order to maintain 0.01 mm tolerance of all elements, magnetic motor components are manufactured using computer-controlled CNC lathes.

The Spider

Another unique solution is a lower suspension commonly called the “spider”. After listening to the prototypes with manifold, even the most advanced spiders available for speaker manufacturers, we agreed that we had to develop our own solution. The issue with the spider is that by being a damper it dissipates the energy, that otherwise would be transferred into the speaker cone. It makes the speaker sound weak and dull, so we knew that it is an unacceptable way to go. We wanted a material that does not absorb energy and only transfers it.

After conducting many tests the solution was found and it turned out to be even better than we expected. It is 100 % linear within the maximum excursion of the speakers ( + – 6mm). It behaves like a spring. It does not consume energy by damping, it just positions the voice coil in the magnetic gap. The downside of such technology is that each spider has to be milled with a precise CNC machine. Nevertheless, the advantages are obvious and totally worth it. In order to measure the actual compliance (amount of excursion under known force) of the suspensions, we designed and custom-made the special device to do the measurements.

Cones and whizzers

Once we had the motor ready and capable to control heavier moving cones and suspensions mass, it was time to do the cones. Plenty of experience for experimenting with 8″ drivers came in handy. We knew where to start with. But that was basically it. 10″ is a completely different beast. For a very long time, we were not satisfied with the sound. There was a time where we didn’t have more bass than from 8″ driver which is basically pointless. Multiple times we had a prototype cone geometry that on measurements was absolutely linear and looking amazing to the point that studio monitor could be really envy, but the sound was dull and boring. Those times were very frustrating. Sometimes we thought that it is impossible to do a really amazingly sounding 10″ fullrange driver. But we never gave up and experimented more and more with even more drive every next day.

It was definitely worth it. The final design consists of 4 cones. One being the main cone and 3 whizzer cones. The smallest cone is responsible for the highest frequency range. With only one standard whizzer we never would never be able to go up to 18 kHz with a driver that in proper cabinet reaches 30 Hz region. So adding that little whizzer, solved one of the issues that we had. But there were plenty more of them. When you add a whizzer to the cone, there is additional interference between the cone and the whizzer. The mini high-frequency whizzer and the main whizzer got together really well and the sound was way better than without it. There was still a geometry issue present though. Its diameter, height, surface, geometry, stiffness, damping, coating all are a part of the final sound equation.

To achieve the right amount of sound pressure in the desired frequency region the most important of them all is geometry. There was one geometry that gave us amazing rich, colourful midrange, but on the other hand, it interfered with the main cone in such a way, that mods were pumping up mid frequencies. Since “shouty” vocals were not desired, we had to do something about it. Here’s where the third whizzer comes into play. That is a very elegant solution to change the interference mods of the whizzer and the cone. Due to changed geometry and distance, the amplitude of the modes decreased. As a result, the overall sound became sweeter, richer and more natural. At that moment we knew that this is the way to go.

Connecting the dots

Thanks to all the technologies that we developed, we got more control over speaker behavior, sound character, frequency response, and Thiele – Small parameters, than ever before. We deeply believe that the drivers that we are presenting to you will satisfy your needs and are the fullange drivers that you were always looking for.

So as you can see, we are obsessed with pushing boundaries and finding the frontier of what’s possible within the fullrange speaker concept. We are driven by our passion and we will never stop looking for the best sound possible. It is not an 8-hour job for us we do it, because we love it. If you share our passion for full range speakers, look no further. You deserve them.

All of our speakers, cones and voice coils are made and manually assembled in Poland. We take pride in our products and we always aim for the highest quality.

Need more information?

Specifications

Fs

30 Hz

Re

5.5 ohms

Le

0.088 mH

Qt

0.5

Qes

0.52

Qms

17.8

Cms

0.76 mm/N

Mms

30 g

Vas

127 litres

Sd

346 cm^2

Bl

8.7 Tm

Xmax

+- 3 mm*

* Voice coil remains in 100% of the magnetic field.

Xdamage

+- 6 mm

Sensitivity

92 dB

Impedance

8 Ohms

Width / height

260 mm

Depth

107 mm

Weight

6 kg